•Ready mix concrete is concrete that is made at ready-mixed plant and then transported to the site in rotating-drum trucks or transit mixers.

•Proportioning, batching, mixing and delivery are all done by the concrete supplier.

•High quality control

•Advantages of using ready mix concrete:

•Proportioning, batching, mixing and delivery are all done by the concrete supplier.

•High quality control

•Advantages of using ready mix concrete:

a) better quality concrete due to usage of trained personnel and automated equipment.

b) elimination of material storage on congested building sites- no need to allocate place at site for storage of cement, aggregate, sand

c) save the contractor’s time and usage of labour’s energy to mix the concrete

b) elimination of material storage on congested building sites- no need to allocate place at site for storage of cement, aggregate, sand

c) save the contractor’s time and usage of labour’s energy to mix the concrete

•For ready mix concrete supply, the purchaser should specify the following:

a) Designated max. size of coarse aggregate

b) Desired / max. slump at the point of delivery

c) Air content (for air entrained concrete)

d) Mix design requirement – such as cement content, max. water content & admixtures or minimum compressive strength at 28 days

e) Unit weight required (for structural lightweight concrete).

a) Designated max. size of coarse aggregate

b) Desired / max. slump at the point of delivery

c) Air content (for air entrained concrete)

d) Mix design requirement – such as cement content, max. water content & admixtures or minimum compressive strength at 28 days

e) Unit weight required (for structural lightweight concrete).

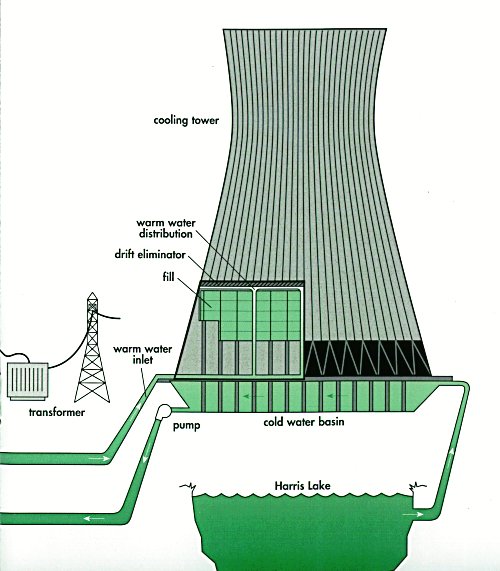

This photo shows a single natural draft cooling tower as used at a

European plant. Natural draft towers are typically about 400 ft (120 m)

high, depending on the differential pressure between the cold outside

air and the hot humid air on the inside of the tower as the driving

force. No fans are used.

This photo shows a single natural draft cooling tower as used at a

European plant. Natural draft towers are typically about 400 ft (120 m)

high, depending on the differential pressure between the cold outside

air and the hot humid air on the inside of the tower as the driving

force. No fans are used.